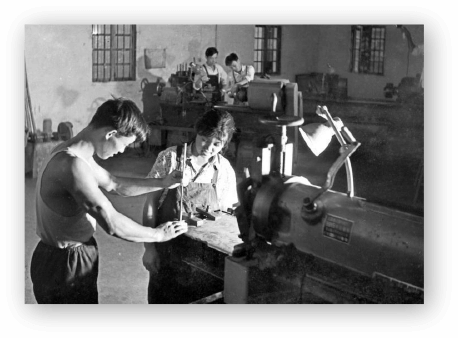

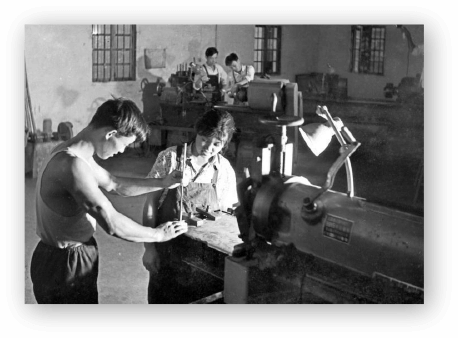

Started from a small workshop, our company began to specialize in machining, including die forging, lathing and hobbing in the early 1980s. Gradually, we manufactured independently and began the mass production.

SCS

Reliable partner when it comes to individual solutions for power transmission parts.

“ SCS ”represents:

Stability · Control· Service

With more than 20 years of experience, SCS is one of the biggest manufactures of sprocket, gears and shafts in China, also a reliable partner when it comes to individual solutions for power transmission parts.

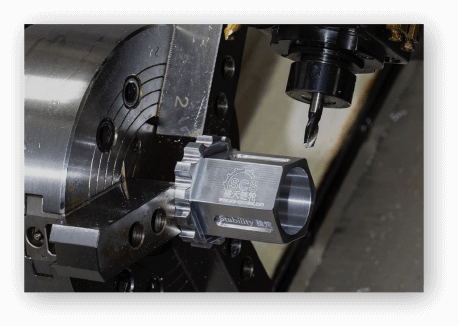

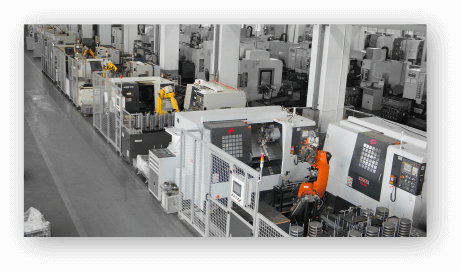

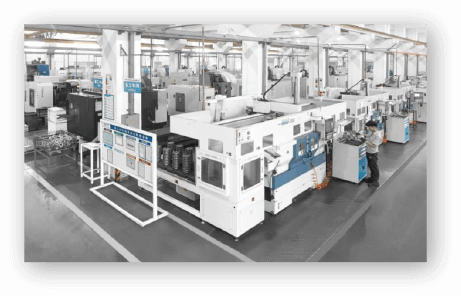

We continuously invest in new production technologies. In order to be prepared for future challenges, we produce standardized as well as highly complex and challenging sprockets, gears and shafts. There are over 300 employees and 500 sets of advanced equipment in the plant. The complete production process, including forging, machining and heat treatment, takes place within our own plant.

There are over a variety of 20,000 specifications for selection. Every year around a thousand of new developed parts with more than a hundred of tests to provide high quality sprockets solutions for worldwide clients.

EST.

1985

Established in

1996

Registered capital

USD

5,000,000

Total investment

USD25,000,000

Floor space

25000m²

Our philosophy didn’t change from the initial stage of pioneering. In order to meet the challenges in the future, we continuously promote technology upgrading, improve the internal management of the enterprise. SCS uses “Focus on the Details”as our slogan. SCS constantly responds to customer expectations, keeps innovating, and continues to create "core manufacturing, new sprocket".

Mission

Committed to creating high-quality transmission components and solutions.

Vision

Become the world's leading supplier of transmission components and build a century-old enterprise.

Philosophy

Produce high cost effective

products through continuous

innovation,raising efficiency

and reducing costs.

Value

Realize the common development of the company and employees,and ultimately create maximum benefits for customers!

SCS Spirit

Be Confident

Believe in yourself:

face the challenge bravely;

never say never in the face of difficulty,

try hard and never give up.

Be Responsible

Undertake courageousl in the face of

difficulty or responsibility, undertake it

courageously instead of drawing

back or evading.

Be a Learner

Make progress positively make progress

positively is an important attitude to

change yourself and improve yourself.

Be a Team Player

Cooperate efficiently: work

proficiently and quickly,

and cooperate well with your colleagues.

Started from a small workshop, our company began to specialize in machining, including die forging, lathing and hobbing in the early 1980s. Gradually, we manufactured independently and began the mass production.

Established Changzhou Ziyun Sprockets Factory

Established Changzhou Chunda Transmission Co., Ltd.

Through introducing foreign capital and expanding production scale, Changzhou Shengtian Transmission Co., Ltd. was established.

The purchase, production and sales realized the information management by adopting ERP system researched a nd developed by ourselves

Establish the brand awareness,SCS trademark was registered

The self-operated export right was authorized by the government. Our ability to further enter into the global market was greatly strengthened.

The workshop was moved to a new site and the workshop area was expanded to 24,000 ㎡from the previous 6,800㎡. The previous simple-equipped workshop turned to be a modernized standard one with a modern office building.

SCS increased investment for the first time, and the registered capital increased from 120,000 USD to 860,000 USD

Imported CNC lathes are put into use, bringing precision processing to a higher level

The Quality Management System Certification of ISO9001 was gained

To meet more strict requirements of our customers, CNC machine was introduced to SCS

The construction of the OEM workshop was finished.

In order to improve R & D ability and establish the brand awareness, the imported CMM was introduced to SCS inspection center

SCS increased investment for the second time, and the registered capital increased from 860,000 USD to 5 million USD

SCS Sprocket successfully passed the quality inspection of the Thailand factory of Mitsubishi Electrics and officially became its sprocket supplier after 18 months’sampling, trial and simulation tests.

After going through strict field investigation, repeated samplings and trial order, SCS became one of the suppliers of Tsubakimoto Chain Co.——the pioneer of world’s top chain and transmission part manufacturers.

Robots were put into use in the production line and production processes were made automatic.

SCS received the message from the headquarter of world’s top agricultural machinery manufacturer CLAAS in Germany that we had successfully passed the inspection of CLAAS headquarter. This not only signifies that SCS has the qualifications to supply products to CLAAS headquarter and its subsidiaries, but it also indicates that SCS has established cooperative relations with world-Claas companies, which will have a great impact on company’s future development.

By renovating the existing ERP system, the new version of ERP system was officially put into use, making the corporate management more effective, regulated and rational.

SCS passed ISO14001—— an environmental management system certification. For a long time, SCS has been committed to reducing the environmental impact of its production and offering more environment-friendly products to customers.The passing of ISO14001 embodies that SCS puts an emphasis on the sustainable development of businesses and the stability of products, thus constantly upgrading the product quality.

SCS invested the capital in purchasing advanced equipment to carry out the technology upgrading programs of large-size agricultural machinery sprockets. The programs successfully passed the inspection and SCS was also rewarded for expediting the industry and corporate upgrading and transformation in the ‘Trinity’ development strategy launched by Changzhou government.

The grand 20th anniversary in celebration of the establishment of SCS was held.

Upholding the operation principle of ‘putting credit first’, SCS was honored as the enterprise of“Following Contract and Observing Credit”by Changzhou government.

SCS was added to the list of ‘Trinity’ enterprises of year 2016. Through constant technological reform and equipment upgrading, SCS expedited its transitioning towards the high-level equipment manufacturing.

With the R&D department being established, we provided a great platform for advancing company’s technology and independent innovation.

Won the "Harmonious Labor Relations Award"

Be recognized as “Following Contract and Observing Credit” enterprise.

Obtained OHSAS18001 occupational health management system certification

With SCS high-quality sprockets manufacturing and warehousing promotion project, it was listed as the city's specialized and special new cultivation enterprise

It was recognized as Tianning district high precision sprocket engineering technology research center

It was recognized as “National High-tech Enterprise”, and until now SCS has applied for and has 18 patents

Obtained the third-level Enterprise qualification of safety production standardization

The annual turnover of 2018 exceeded 100 million

Won the annual "Science and Technology Innovation Award" and "Tax Sales Increase Award"

In order to deepen the development, SCS changed the name from “Shengtian SCS Transmission Co., Ltd” to “Changzhou SCS Sprocket Transmission Co., Ltd”

SCS high precision sprocket engineering technology research center was selected into the list of Changzhou Engineering Technology Research Center which announced by the Municipal Science and Technology Bureau

The Municipal Bureau of industry and information technology announced that our company was shortlisted: Changzhou "Trinity" special award in 2019, so as to speed up the effective investment of enterprise projects

The Municipal Bureau of industry and information technology announced that our sprocket intelligent plant was appraised as Changzhou intelligent plant

Mr. Qiang Chun, general manager of SCS, and his team were invited to attend global suppliers conference held by Claas KGaA MBH in Germany. Among 2,100 suppliers which are from 42 different countries all over the world, SCS won the Claas“The Best Quality Award”for its excellent quality, timely delivery and high quality service. SCS has demonstrated its strength to the international machinery manufacturing industry and obtained high recognition from customers.

The world famous agri cultural machinery and agricultural vehicle man ufacturers.

A world-renowned leading supplier of automated stor age solutions and material handling systems.

The world's famous agri cultural machinery giant business division more than 160 countries.

Famous transmission parts manufacturer in Japan.

Famous for its innova tive and cutting-edge products and system solutions.

For a variety of process technology, filling technology and packaging technology development planning and manufacturing machines and equipment package.

With a history of more than 120 years, it is the largest agricultural machinery man ufacturer in Japan.

A world famous multina tional group.

International top trans mission brand, technical leader in transmission system field.

Founded in 1882, Mädler manages high quality construction industry ac cessories.