R&D

International advanced precision sprocket engineering technology research center

Technological Achievements

On the basis of independent development and accumulation, SCS R & D center also actively cooperates with the outside world. The annual R & D investment accounts for more than 5% of the sales revenue. More than 10 new product R & D and technological innovation projects have been completed every year. At the same time, more than 30 national patents have been declared, among which 25 national patents have been authorized, and the remaining patents are in the stage of this batch.

R&D

Precision sprocket engineering technology R&D center

1,520m² of office space, including 400m² for R&D, 120m² for testing and 1,000m² for pilot test. There are chemical analysis room, metallographic laboratory, performance laboratory and pilot plant, equipped with advanced inspection facilities and production equipment. Set up a research center, relying on the center's increasing technological innovation ability, to realize the flexible customized production of the company's special sprockets and other parts, and reach the advanced level of domestic and international transmission parts.

Forging production line

Turning Automatic production line

Machining center production line

Hobbing automated production line

Be strict from the source

After strict selection of raw materials, through the repeated forging of high-pressure casting machine, the initial state of the product is formed. From the moment of birth, the service life of the product is determined.

Ingenuity is inseparable from manual welding of an experienced craftsman

A seemingly simple step requires craftsmen with more than 10 years of experience, meticulous manual welding, focusing on quality and appearance, which is enough to make competitors eclipse.

Directional development

Facing the demand of different application fields, we draw and model the product system that users need, quickly define multiple variables, use 3D model viewer and new sketch tool module.

Intelligent production and management

Precise data calculation, precise ERP management module, high-precision production equipment, one click intelligent batch production, compact, fast and efficient, maintain the highest quality and continuously improve efficiency.

High quality needs to go through many processes

Chamfering, grinding, turning and milling, similar to diamond level process, high requirements to ensure that the product performance, quality and innovation all exceed the expectations of customers.

Good products, from the multiple detection

As your professional partner, we advocate products with “Zero defects”. All products must go through multiple and strict quality inspection to form an action closed loop of high quality production, which is also a strong guarantee for SCS to become a reliable partner of many famous brand manufacturers in the world.

QC

From manufacturing to application, we take every chance to improve our quality. SCS produces parts that have to function with

zero defects: high precision is our requirement. Our production process is always monitored by

strict quality control and analysis. Our quality management system, regular control of measuring and testing equipment,

as well as high qualified employees help to ensure the compliance with the highest quality standard.

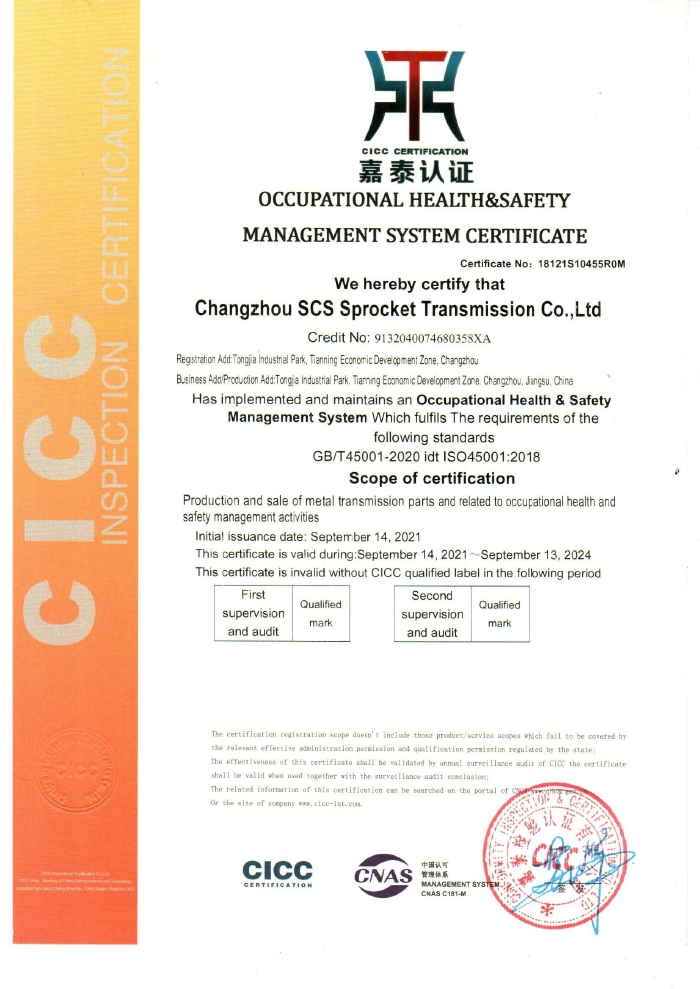

SCS passed the international system certification of ISO9001/ISO14001/OHSAS18001.

ISO 9001

Quality control system

Passed ISO9001 International Quality

Management System Certification since 2009

SO 14001

Environmental management system

Passed ISO14001 International Environmental

Management System Certification in 2015

OHSAS 18001

Occupational health management system

Passed OHSAS18001 Occupational Health and Safety

Management Systems Certification in 2007

High quality

Customer satisfaction assessment and

satisfaction activities

Process / product compliance verification

Cost controllable

Through process innovation

Enhance cost competitiveness

Complete delivery

Deliver on time before the

delivery date given by the customer