General Products

A variety of products that meet high standards

All types of sprockets are made of high quality C45 steel; stainless steel parts, such as SUS304 can be customized;

In line with JIS / DIN specifications, it is widely used in agriculture, logistic conveyor, food processing, packaging, stereo garage, printing and other industries;

High frequency quenching and tempering can improve the strength and service life of sprocket teeth;

We can provide products with finished inner bore diameter, keyway and thread. Customers do not need to carry out follow-up manufacturing. We can also customize the inner bore, keyway, thread and surface treatment according to customer needs.

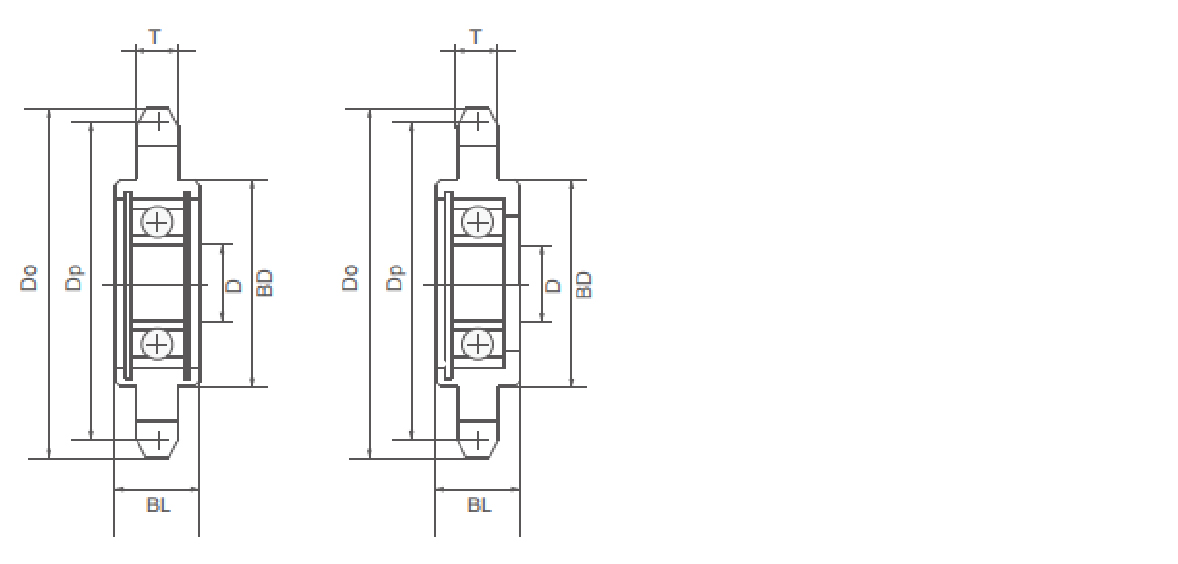

Chain coupling is a coupling that composed of two rows of roller chains and two sprockets that engaged with them.

One end of the chain is equipped with a joint pin which can be inserted or pulled out freely. It helps to simplify the connection and disassembly.

Along the direction that perpendicular to the shaft, the cover can be separated into two parts. V-grooves are set on both sides of the cover of KC3012~KC8022, and O-rings are installed to prevent oil leakage.

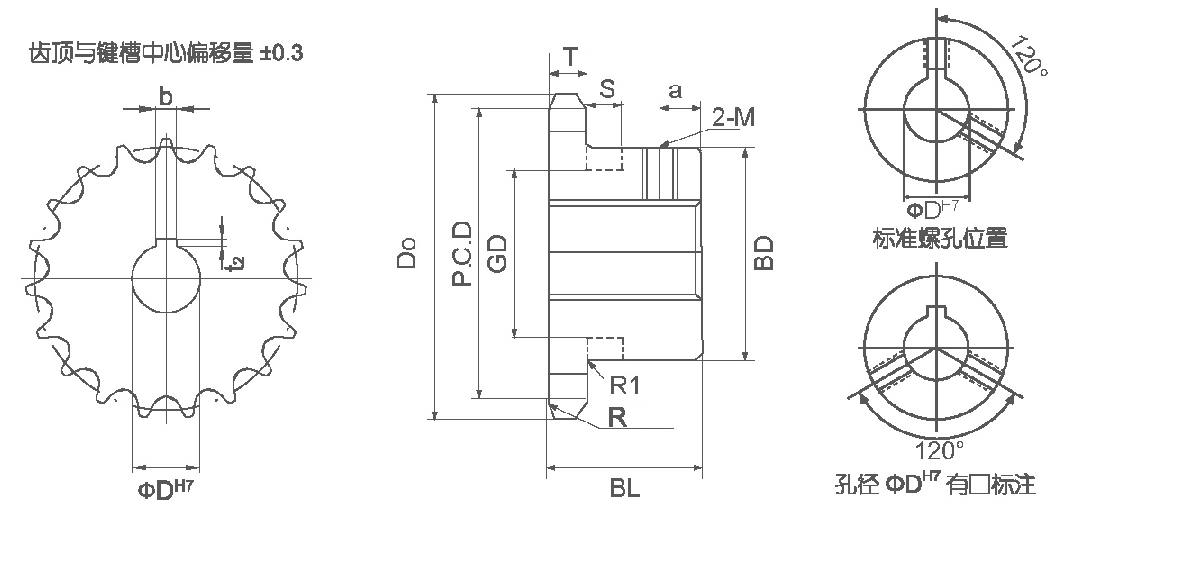

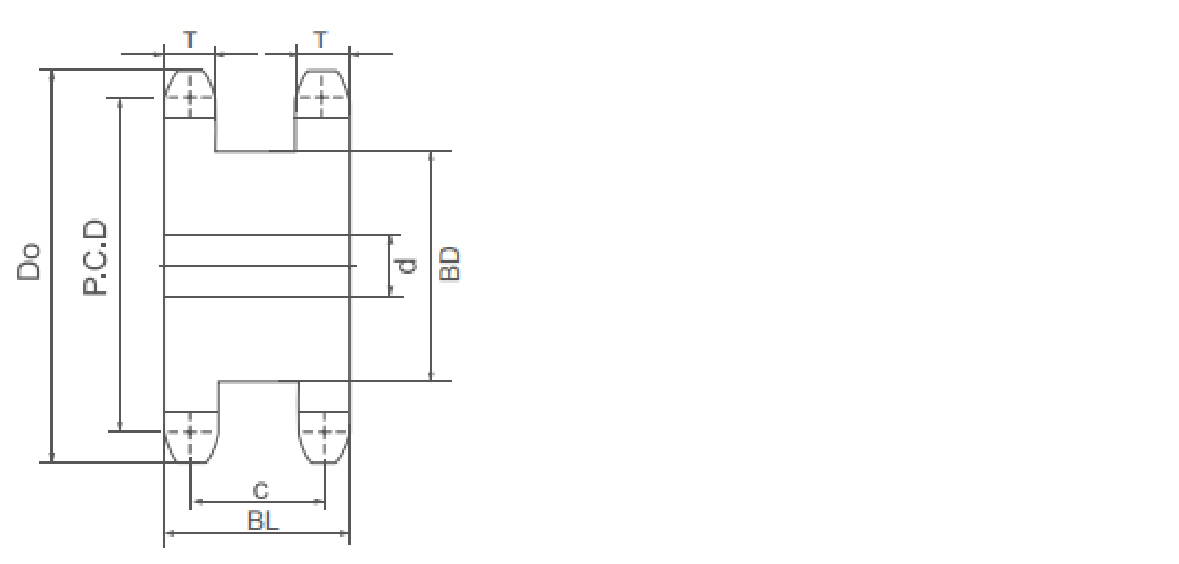

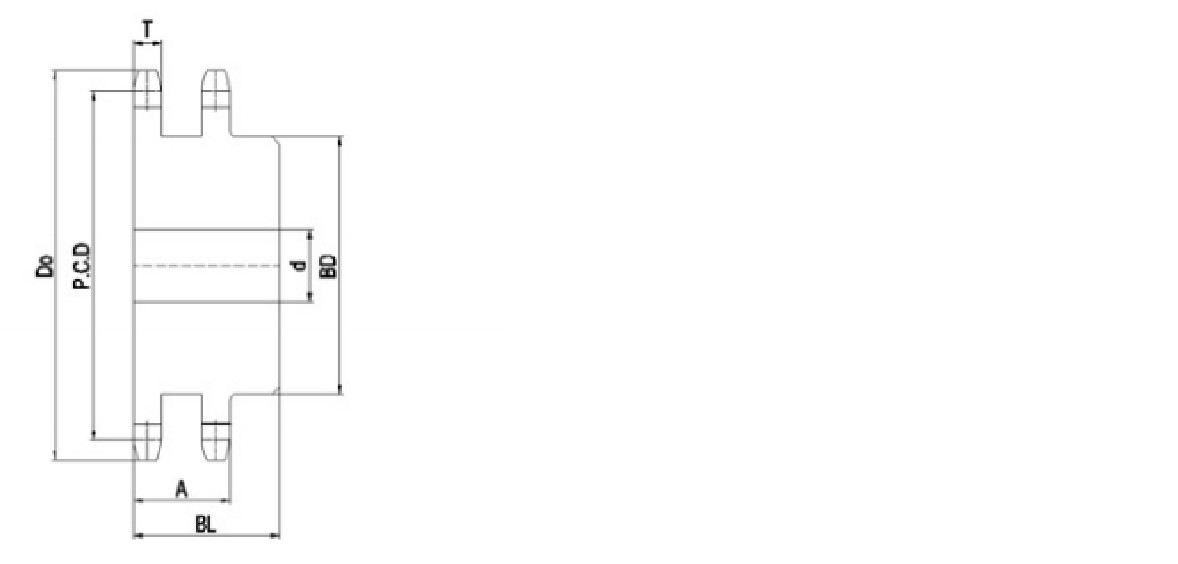

Double single sprocket is designed for two single roller chains. The sprocket is made of high quality raw material C45 with teeth harden. The maximum inner bore diameter shown in the table below are based on commonly used operating conditions — sprocket with standard keys and set screws. The actual inner bore diameter depends on the general mechanical design, and the fitting tightness of the key is also determined according to the design requirements.

R-type roller chain sprocket: R-type roller chain sprocket is a double pitch sprocket with single cutting teeth.

S-type roller chain sprocket: this type of sprocket is a double pitch sprocket with variable cutting teeth. The number of teeth of the sprocket is fixed. Every time the sprocket rotates, the chain will mesh with one of the two adjacent teeth. The number of teeth is defined as the "number of working teeth". In the case of odd number of teeth, the sprocket turns twice to make each tooth mesh with the chain once, thus prolonging the life of the sprocket.

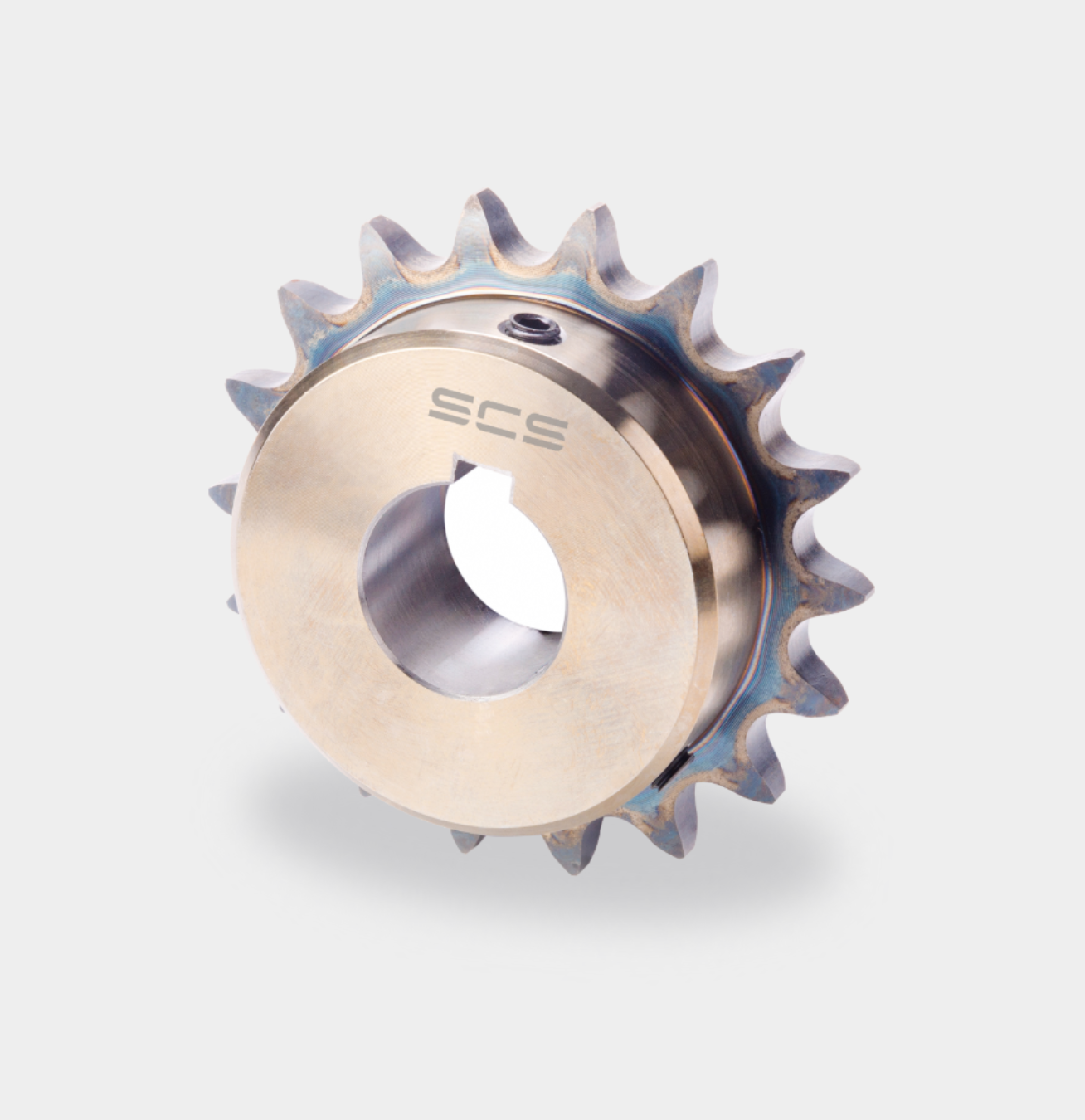

SCS standard idler sprocket can maintain proper tension during the transmission of roller chain. Heat treatment of the sprocket teeth helps to make excellent durability, smooth and quiet rotation.

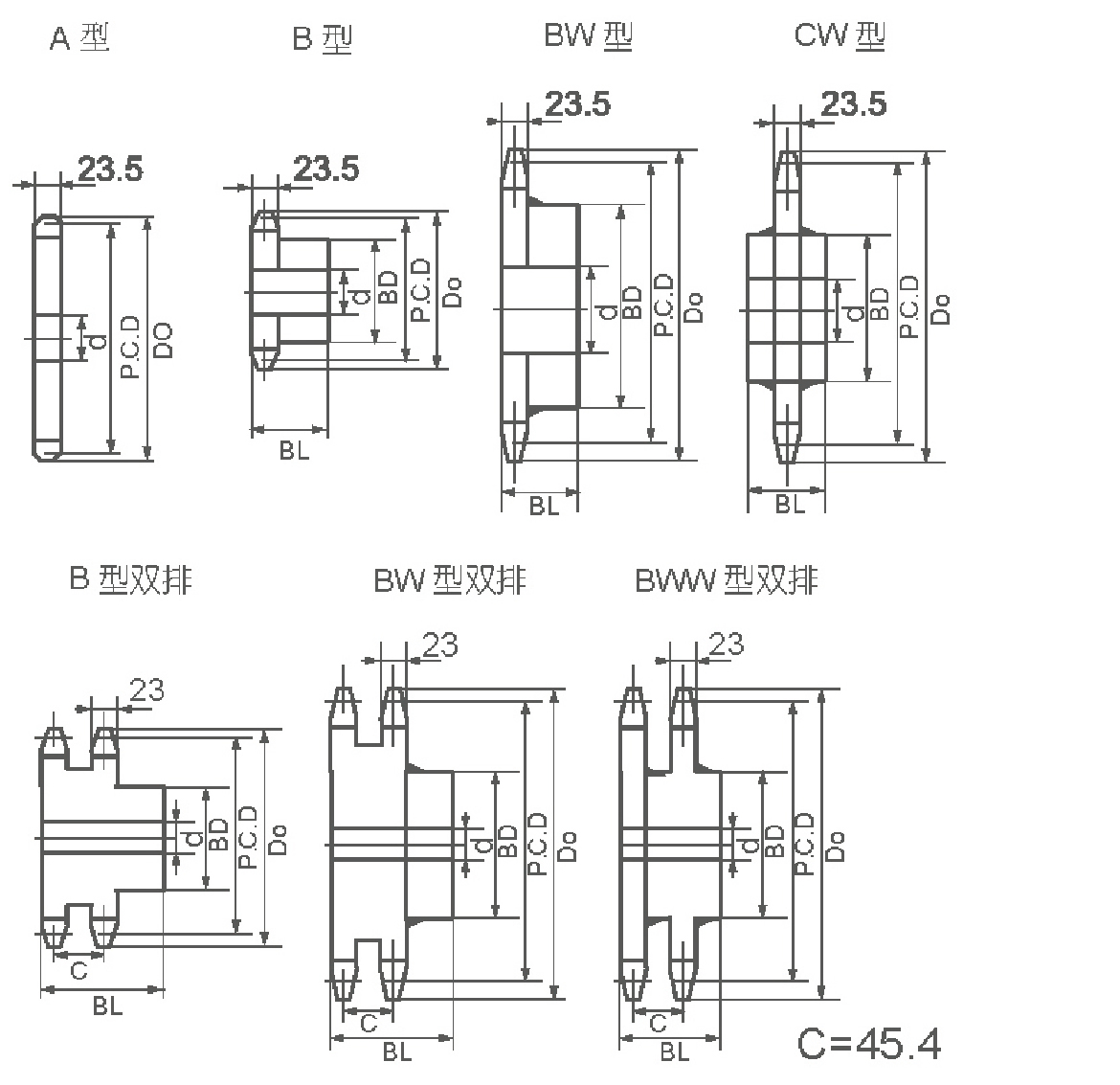

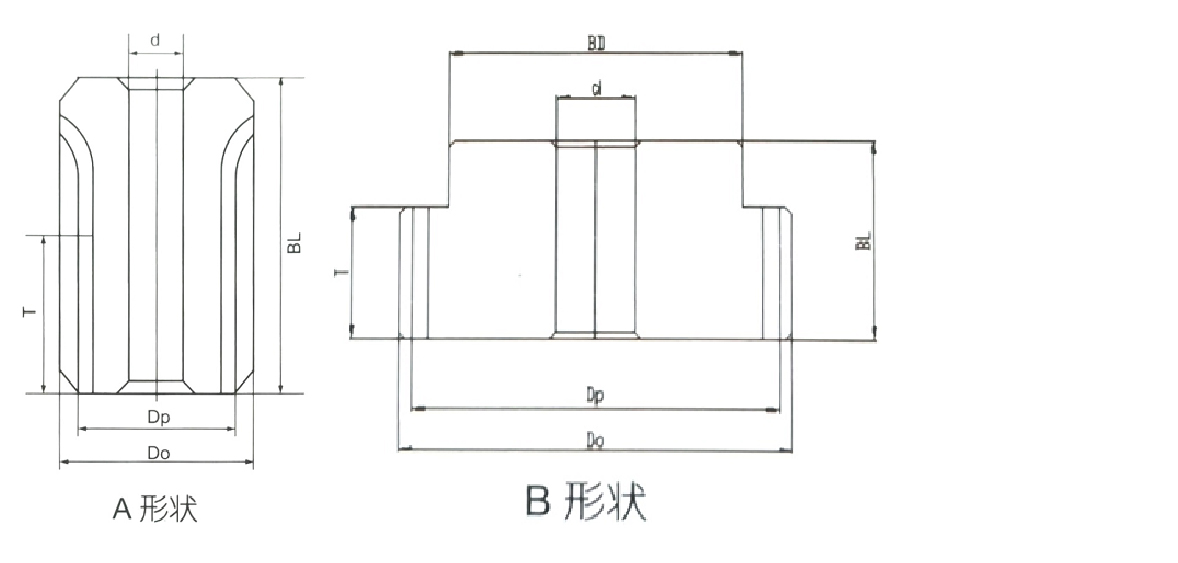

SCS standard conveyor sprocket is produced by milling technology of the machining center. The special tooth profile designed by SCS can minimize the roller movement and allow smooth normal reverse movement. The inventory of SCS standard conveyor chain sprocket is divided into type A, B and C. Type A and special hub can be quickly welded into the required type of sprocket. If high strength and high wear resistance sprocket are required, the tooth can be heat treated as required.

Spur gear is the most common gear that drives between two parallel shafts.

Because the gear tooth surface is parallel to the axis of the assembly shaft, the spur gear does not generate thrust (axial force) in transmission.

In addition, the spur gear is comparatively easy to produce, so it can make high precision gear.

Preessure angle20*

SUS Stainless steel material makes sprocket with high hardness,high temperature resistance and corrosion resistance.